When people discover a problem with their clutch release bearing, their first reaction is often, "Can I still manage to drive it for a while?" While the car might not be completely incapacitated yet, driving with a faulty clutch release bearing is like carrying a ticking time bomb. Here's an analysis of driving with ...

READ MORE-

-

Although clutch release bearings are designed to be durable, they are also quite delicate, and many everyday habits can unknowingly shorten their lifespan. Here are some of the main reasons for their damage: 1. The Habit of Keeping Your Foot on the Clutch Pedal This is the most common cause of bearing damage. Many dr...

READ MORE -

The cost of replacing a clutch release bearing (also commonly called a release bearing or thrust bearing) mainly consists of two parts, but the most painful part is often not the cost of the part itself, but the expensive labor costs. Here's a breakdown of the repair costs: 1. Cost of the part itself Bearing unit pri...

READ MORE

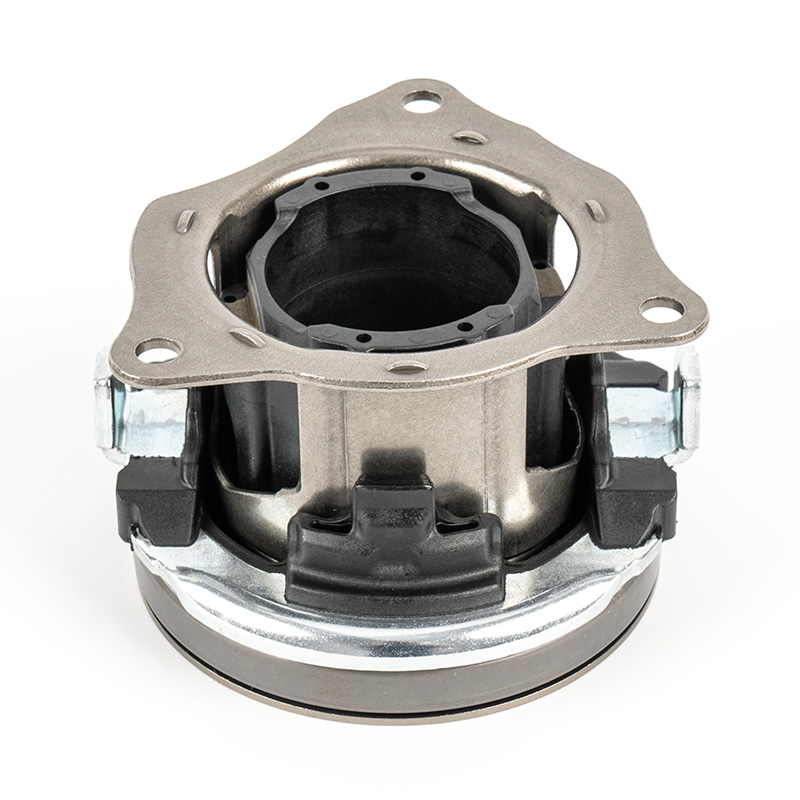

A dual clutch release bearing is a critical component in modern automotive transmission systems, specifically designed for dual clutch transmissions (DCTs). This bearing facilitates the precise engagement and disengagement of clutches, enabling seamless gear shifts and improved vehicle performance.

Concept and Function

A dual clutch release bearing, also known as a clutch release bearing or throw-out bearing, is a mechanical device that operates within a DCT system. Its primary function is to actuate the clutch mechanism by applying force to the clutch diaphragm spring or pressure plate, allowing for the disengagement of the clutch plates during gear changes. In a DCT, which employs two separate clutches—one for odd-numbered gears and another for even-numbered gears—the release bearing ensures synchronized control over both clutches. This enables rapid shifts without interrupting power flow, contributing to enhanced efficiency and drivability. The bearing typically interfaces with the clutch hydraulic or electronic actuation system, translating input signals into mechanical movement.

Types of Dual Clutch Release Bearings

Dual clutch release bearings are categorized based on their actuation mechanisms and design features. Common types include:

Hydraulic Release Bearings: These utilize hydraulic pressure to operate the clutch mechanism. They are integrated into the transmission hydraulic system, offering precise control and smooth engagement. Hydraulic bearings are widely used in high-performance and luxury vehicles due to their responsiveness.

Electric or Electro-Mechanical Release Bearings: These employ electric motors or solenoids for actuation, often controlled by the vehicle's transmission control unit (TCU). They provide flexibility in packaging and are common in modern DCTs for their efficiency and compatibility with electronic systems.

Mechanical Release Bearings: Less common in DCTs, these rely on mechanical linkages such as cables or levers. They are typically found in older or simpler transmission designs but may be used in specific applications for cost-effectiveness.

Each type is engineered to meet specific performance criteria, such as durability, response time, and compatibility with transmission architecture.

Applications

Dual clutch release bearings are predominantly used in dual clutch transmissions, which are implemented in various vehicle segments, including passenger cars, sports cars, and commercial vehicles. DCTs are favored for their ability to combine the efficiency of manual transmissions with the convenience of automatics. In these systems, the release bearing ensures optimal clutch operation during acceleration, deceleration, and gear shifts. Applications extend to hybrid and electric vehicles, where DCTs are adapted for improved energy recovery and powertrain integration. The bearing's role is crucial in maintaining transmission reliability and performance under diverse driving conditions.

Comparison with Other Release Bearings

Dual clutch release bearings differ from single clutch release bearings in several aspects:

Design Complexity: Dual clutch systems require bearings that can manage two independent clutches, often involving more intricate components and control logic compared to single clutch bearings, which handle one clutch.

Performance: Dual clutch bearings enable faster shift times and reduced power loss, as they allow pre-selection of gears. Single clutch bearings, common in manual transmissions, may result in brief torque interruption during shifts.

Durability and Maintenance: Dual clutch bearings are subject to higher thermal and mechanical stresses due to frequent actuation. They often incorporate advanced materials, such as high-grade steels or composites, to enhance longevity. In contrast, single clutch bearings may have simpler maintenance requirements but lower efficiency in high-performance scenarios.

Cost and Integration: Dual clutch systems, including their bearings, generally involve higher manufacturing costs and complexity. However, they offer benefits in fuel economy and driving dynamics, making them suitable for applications where performance is prioritized.

This comparison is based on functional characteristics rather than subjective evaluations.

Frequently Asked Questions (FAQ)

What is the typical lifespan of a dual clutch release bearing?

The lifespan varies based on driving conditions, maintenance, and design. Under normal operating conditions, it can last between 100,000 to 150,000 miles. Aggressive driving or inadequate lubrication may reduce this range.

How can one identify issues with a dual clutch release bearing?

Common symptoms include unusual noises (e.g., grinding or whining during clutch operation), difficulty in shifting gears, or clutch slippage. Diagnostic tools and professional inspection are recommended for accurate assessment.

Are dual clutch release bearings serviceable?

In many designs, they are not serviceable individually and may require replacement as part of a clutch assembly. Maintenance schedules should adhere to manufacturer guidelines.

What factors influence the performance of a dual clutch release bearing?

Key factors include actuation system type (hydraulic vs. electric), material quality, thermal management, and alignment within the transmission. Proper lubrication and calibration are essential for optimal function.

Can dual clutch release bearings be used in non-automotive applications?

While primarily designed for automotive DCTs, similar principles may apply in industrial machinery requiring precise clutch control, though adaptations would be necessary.

In the automotive parts industry, manufacturers such as Xinchang Heyang Auto Parts Co., Ltd. specialize in producing a wide range of clutch release bearings, including over 300 types tailored for vehicles from Japan, Korea, Germany, the U.S., and others. With advanced manufacturing equipment and stringent quality control, such companies ensure that these bearings meet durability standards, often supporting performance for over 50,000 kilometers. Products from suppliers like these are distributed across key markets including the Middle East, Southeast Asia, South America, and Europe, aligning with a customer-focused approach to deliver precision and reliability in every component.

+86-13867573512

+86-13867573512