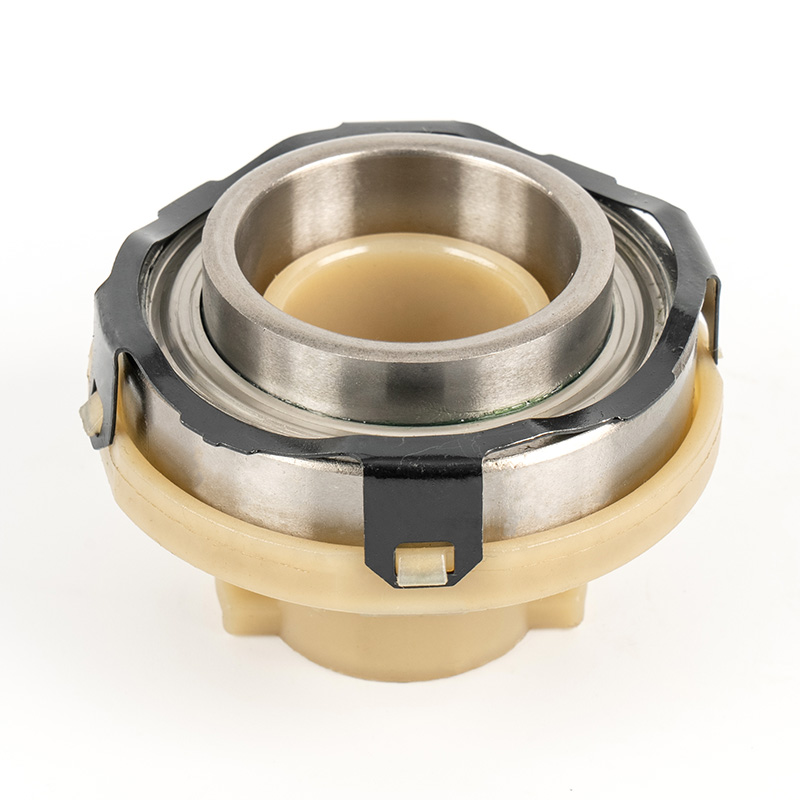

As the core component of the transmission system of LADA models, this series of clutch release bearings adopts a high-precision single-row ball bearing structure, which is specially designed to cope with high-load and high-frequency separation conditions. Its core advantage is that by optimizing the sealing system and grease formula, the operating friction coefficient is significantly reduced, ensuring that the stable separation force output can be maintained under extreme temperature environments of -40℃ to +120℃. The inner and outer rings of the bearings are made of high-carbon chromium bearing steel with an overall quenching process, and the surface hardness reaches HRC60-64. With phosphating anti-rust treatment, it effectively resists clutch splash oil and road salt spray corrosion, and extends the service life to more than 1.8 times that of traditional products.

This product controls the vibration amplitude within 0.15mm through dynamic balancing correction technology, greatly reducing the vibration of the clutch pedal and improving the smoothness of gear shifting. Its separation finger contact surface adopts a special arc design, and the fit with the LADA original clutch pressure plate separation lever is increased by 30%, ensuring the accuracy of power transmission. In addition, the clearance compensation mechanism between the bearing and the transmission shaft has been verified through 200,000 times of endurance testing. It can automatically eliminate the axial movement caused by long-term use, maintain an optimal separation clearance of 3-4mm, and avoid bearing ablation caused by incomplete separation due to excessive clearance or too small clearance, providing long-lasting and reliable transmission protection for LADA models.

+86-13867573512

+86-13867573512